Well, here we are at the starting position. I have a group coming this weekend and I have to get the panel done. In lieu of a hinge, I placed two clamps onto the bench work to hold the panel while I do the wiring. I have painted the panel in a reverse fashion as it is a piece of 1/8th inch Plexiglas. First I paint the background (after putting tape on to represent the track, and then I paint the track color. I had a little problem with the track color as it attacked the previous coats so I will have to remake the panel after the visitors leave.

Now I have flipped over the panel to show where I have to work. All the switches are in place. It is nice and white as I painted that for the track color.

Here we are in process as I am soldering the wires to the switches. I am also having to check the functionality of each switch as I go so I do not have to do too much backtracking to solve problems later. This involves getting up on a ladder and looking at the track direction as I through the turnout switch. Up and down, up and down. We are controlling the holding loop hanging from the ceiling.

The wiring is complete and I am beginning to put the wraps in place to make it a little neater.

We now have the panel in place and operational. Total elapsed time to do just the wiring - 3 days of free time. The black hole to the right is the frame for the next piece of panel which will hold two small TV screens to show the position of the trains at the ceiling.

Monday, November 11, 2013

Sunday, October 20, 2013

The start of wiring

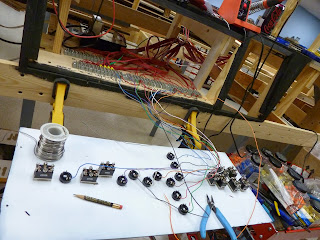

Well, one of my goals for this year was to get some wiring done so I can operate the trains more effectively. Right now, a simple feed to the tracks powers the whole layout. So, I have begun at the finish of the branchline. It is a return loop so I cannot run it until I get some wiring done. Here is the start of the terminal strips that will contain the track power blocks and the turnouts. You can tell, I am not a neat-nick when it comes to routing the wire. That plus no color code makes it seem like a jumble. I do label the terminal points so I know what I have to hook up to the control panels. I also have a paper diagram of what I want to accomplish with my wiring plan.

Here you can see what we are trying to control. We have an engine and a test boxcar up on the branchline terminal - Mount Carmel - I need to build the panel on the aisle in the foreground. So, I have several cables running from up there to the aisle. I also have a cable coming down from the ceiling (you can see it just above the right end of the boxcar) which has to be included. You can also see the connections from the track above to the red wiring that merges into the cable.

This is an overview that shows the gathering of the tools, paperwork on the circuits, meters and a power pack for testing. You can see the terminal strips on the benchwork. This panel will control all the tracks in that overhead loop that is hanging from the ceiling. The engine and boxcar is poised to go into the loop to the right.

The cables will run in the walls from the upper tracks to the lower support area and then to the terminal strips. Those cables have been hanging there for about 3 years while I built up to that hanging track. The engine has run around those tracks with the test boxcar as I am wiring the loops.

This is a view from the other side and you can clearly see the cables that will run inside the walls.

This view from the end shows the cable run and the ties to the wall members.

Here you can see what we are trying to control. We have an engine and a test boxcar up on the branchline terminal - Mount Carmel - I need to build the panel on the aisle in the foreground. So, I have several cables running from up there to the aisle. I also have a cable coming down from the ceiling (you can see it just above the right end of the boxcar) which has to be included. You can also see the connections from the track above to the red wiring that merges into the cable.

This is an overview that shows the gathering of the tools, paperwork on the circuits, meters and a power pack for testing. You can see the terminal strips on the benchwork. This panel will control all the tracks in that overhead loop that is hanging from the ceiling. The engine and boxcar is poised to go into the loop to the right.

The cables will run in the walls from the upper tracks to the lower support area and then to the terminal strips. Those cables have been hanging there for about 3 years while I built up to that hanging track. The engine has run around those tracks with the test boxcar as I am wiring the loops.

This is a view from the other side and you can clearly see the cables that will run inside the walls.

This view from the end shows the cable run and the ties to the wall members.

Friday, August 30, 2013

Scenic Divides

One of the theories in layout construction is that you only want the viewer to see one scene at a time as they look at the trains. That places the train, then, in some sort of context with the landscape around it. As you have seen in all my pictures, you can see the entire room to this point. So, now I have to divide the room into discrete scenes. This is the beginning of that exercise. I have built a half stud wall that will be faced with a sandwich of Masonite and plastic to form that wall. This shows the curved ending to the wall where the main line will disappear into a tunnel on the lower level. On top of the wall, the tracks hanging from the ceiling form the sky. You can see in this view that the walls diverge with the front one ending, and the rear one starting to proceed to the left.

This is a view that shows the rear wall moving left along the railroad yard while the right wall curves out to the end of the benchwork and stops. I have purchased 14 sheets of Masonite for the wall backer. I plan to build more stud walls before I hang that material. Key to this exercise is to get the wall vertical and have the curves smooth so I can bend the material without problems and without having the backer climbing up the studs (if it is not vertical). Thus it will take time.

This is a view from the entrance to the yard, of how the wall will appear as it rises up to the bottom of the structure that holds the 6 overhead tracks. I had to build this first to hold the wiring that drops down from the overhead tracks to a control panel that I have to build about where I am standing. You can see the red wire dropping down in the background. So, I will probably stop this as I do some wiring.

This is a view that shows the rear wall moving left along the railroad yard while the right wall curves out to the end of the benchwork and stops. I have purchased 14 sheets of Masonite for the wall backer. I plan to build more stud walls before I hang that material. Key to this exercise is to get the wall vertical and have the curves smooth so I can bend the material without problems and without having the backer climbing up the studs (if it is not vertical). Thus it will take time.

This is a view from the entrance to the yard, of how the wall will appear as it rises up to the bottom of the structure that holds the 6 overhead tracks. I had to build this first to hold the wiring that drops down from the overhead tracks to a control panel that I have to build about where I am standing. You can see the red wire dropping down in the background. So, I will probably stop this as I do some wiring.

Thursday, August 29, 2013

More turntable

Well, I have added about 7 coats of plaster to make the pit somewhat smooth. I used a wet sponge between coats to even things out and then drew a putty knife over the surface when it was wet to get the best finish.

If you recall, we had a rather grossly oversize pit rail when we started this. I have now made a smaller pit rail using Micro Engineering flex track that I cut in half on a band saw. I sized it off the original one which I had removed. I finished the sizing by putting the rail into the pit and marking it for the final cut.

It loos so much better making the project worthwhile.

Next, I have to do the painting of the pit, the rail and the wall. More later.

Turntable continued

Well, as I mentioned, I have to cover the gap between the ring rail base and the pit bottom. Plus, I have to make the pit bottom taper as the real one would have to facilitate drainage. So, I cut a sloped edge to some styrene plastic, sized to fit the base.

This is how I will use it to screed the plaster as I put it in. In the event, it actually took multiple coats of plaster.

I drew some circular lines to guide the plastic as I drew it around the ring.

We are putting our first coat of plaster into place. I roughly shaped it with the plastic as I knew I would have to recoat this several times.

Here is the big bucket of spackling compound purchased at Lowes. In O scale you go through lots of these buckets!

Another view of the first coat. I wanted to seal up the gap as a first step.

Again, using the plastic shaping tool. You can tell I get into my work.

This is a view of the whole pit after the first coat.

This is how I will use it to screed the plaster as I put it in. In the event, it actually took multiple coats of plaster.

I drew some circular lines to guide the plastic as I drew it around the ring.

We are putting our first coat of plaster into place. I roughly shaped it with the plastic as I knew I would have to recoat this several times.

Here is the big bucket of spackling compound purchased at Lowes. In O scale you go through lots of these buckets!

Another view of the first coat. I wanted to seal up the gap as a first step.

Again, using the plastic shaping tool. You can tell I get into my work.

This is a view of the whole pit after the first coat.

Sunday, July 14, 2013

The Turntable - Part one

Well, nothing is easy. I am starting to lay the track in the steam terminal and I realized I had the get the turntable set up so I could align the tracks coming in. I had purchased a Mill House Studio turntable which is a very nice unit but made for 3-railers. While making it sturdy, he used a way over size garden railway track for the ring rail. So, I had to remove the entire ring rail assembly to put in scale sized rail to support the bridge.

Here we have the ring rail support out of the table pit. He made them from nice birch plywood. It was a problem getting them out as he had them screwed in from the bottom so I had to remove portions of the drive assembly to get at the screws.

This is the offending ring rail which I will use as a template for my new one. You can see it looks rather large.

You can see how much bigger it is than one made from a scale sized rail would be. The foreground track is what I am going to use. It is from Micro Engineering and the ties are so firmly mounted to the rail, I think I can rip the track in half and not have a problem with them shifting. The scale rail is about half the height of the over sized stuff. This brings up the next problem. The bridge of the turntable is supported by the ring rail assembly. Thus, it will be too low to meet the tracks around the turntable unless we raise the base for the ring rail. We have to raise it 0.20 inches. Not an easy number as it is not a standard dimension.

Well, I found some old cabinet trim that was 0.185 in thickness. Now you know why I never throw anything away! The rail I am using on the bridge is 0.015 higher than the rails around the turntable so we are now close enough. I cut the trim into short pieces to fit around the ring.

Here you see the supports glued to the bottom of the pit and the ring rail base going back in.

The base is now in and screwed down from underneath. That wire sticking up is to power the ring rail from below.

I have sealed the seams with some wood putty and am letting it dry before sanding it.

You can see the gap of additional height that we have created. I am now going to make a plastic template to put in the slope of plaster that will close the gap and simulate a pitched surface that would drain the water to a ring area around the pit, away from the center bearing and the ring rail. More on that later.

Here we have the ring rail support out of the table pit. He made them from nice birch plywood. It was a problem getting them out as he had them screwed in from the bottom so I had to remove portions of the drive assembly to get at the screws.

This is the offending ring rail which I will use as a template for my new one. You can see it looks rather large.

You can see how much bigger it is than one made from a scale sized rail would be. The foreground track is what I am going to use. It is from Micro Engineering and the ties are so firmly mounted to the rail, I think I can rip the track in half and not have a problem with them shifting. The scale rail is about half the height of the over sized stuff. This brings up the next problem. The bridge of the turntable is supported by the ring rail assembly. Thus, it will be too low to meet the tracks around the turntable unless we raise the base for the ring rail. We have to raise it 0.20 inches. Not an easy number as it is not a standard dimension.

Well, I found some old cabinet trim that was 0.185 in thickness. Now you know why I never throw anything away! The rail I am using on the bridge is 0.015 higher than the rails around the turntable so we are now close enough. I cut the trim into short pieces to fit around the ring.

Here you see the supports glued to the bottom of the pit and the ring rail base going back in.

The base is now in and screwed down from underneath. That wire sticking up is to power the ring rail from below.

I have sealed the seams with some wood putty and am letting it dry before sanding it.

You can see the gap of additional height that we have created. I am now going to make a plastic template to put in the slope of plaster that will close the gap and simulate a pitched surface that would drain the water to a ring area around the pit, away from the center bearing and the ring rail. More on that later.

Friday, July 5, 2013

Our First Open House

I built some temporary panels at Milton and Herndon so we could operate the hidden holding tracks on the main. I then staged 6 trains, 3 each westbound and eastbound, including a K5 powered local passenger.

Here is a leased Reading 4-8-4, a T1, pulling through Northumberland westbound. The PRR leased them in the summer of 1956 to supplement their steam power during the summer.

An action shot going by the Shamokin drag leaving to go up the branch.

And now it is going away.

Here is an upgraded L1, 2-8-2, headed eastbound to Harrisburg with a mixed freight. I made this model by using a Precision K4 boiler, redetailed it, and then mated it with a US Hobbies frame and drivers.

Our closing shot is the T1 coming into Milton on its journey west.

All this told me that I have to put some cameras in to monitor the hidden area as I had a heck of a time keeping track of the 6 trains. So, I have now purchased 4 closed circuit TV cameras and screens to be able to see what is going on. Now I have to read up on how to hook them up. The screens are actual 7 inch TV's that would be used in automobiles or other small areas. More on this later.

Subscribe to:

Posts (Atom)