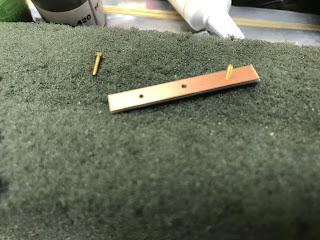

So, I fabricate the throw bars from double sided printed circuit boards that I cut in to 1/4-inch-wide pieces about 2.5 inches long. I drill three #56 holes along the centerline. The outer two holes are spaced 28/32" of an inch apart. Then I put 00-90 screws into the two outer holes to secure the Right-O-Way points. I use 16-foot points for these #5 and #6 turnouts.

The screws stick up enough for me to get the points mounted on the layout. They just barely fit into the holes.

Then I solder the screws to the bottom of the two-sided PC board. No worries about these coming out in service.

Lastly, I cut the cladding on both top and bottom so there is no conductivity between the points which are powered from the stock rails, along with the diverging route rails. This makes them suitable for DCC as well as DC.

Next you will see them installed.

No comments:

Post a Comment